AI Products

Specialized in your content

Dharma-AI KM Maintenance

A unified source of all textual and tacit knowledge about YOUR PLANT

-> We offer an AI chat specialized in your Operation and Maintenance content that allows your factory team to ask any question and get answers in Natural Language, even helping the user to complement their question with additional queries.

- Solution accessed via computer, totem, tablet, or mobile phone.

- Dashboards and screens with the entire unified history of actions on each machine in your Asset Tree.

AI and the problem of maintenance in large production lines

Reduction in interruptions and failures in production lines

-> Large factories and continuous production lines are highly complex and high-productivity structures.

-> Even with all available technology, simple situations continue to impact the OEE and overall plant productivity due to unplanned downtime, longer downtime than planned, or longer restart times than expected.

Knowledge, maintenance, and performance

-> Much progress has been made in sensors (IoT or IIoT) and the use of failure prediction algorithms (Machine Learning). However, the textual knowledge of operation and the real day-to-day of Maintenance still remains siloed and disconnected in most large continuous production lines.

-> Not to mention the tacit knowledge of experienced operators or maintenance technicians and engineers, which has been built over years of running that production. Such explicit or tacit knowledge is essential for better performance in large factories.

Much effort around recurring problems

-> Simple questions like these continue to demand great effort or a lot of time to answer:

- How much is spent to read all General Downtime Reports and organize all actions taken and recommended to plan your next General Downtime?

- What procedures were performed, along with the replacement of a specific part, during the last general downtime or planned maintenance?

- Who performed the last replacement of a specific part on the machine and how long did it take? Would this technician have any practical tips on how they performed the procedure?

- What Recommended Activities from the last General Downtime have we already performed in our routines and no longer need to be requested?

- What is the quality of the knowledge record in your Tickets or Maintenance Orders?

- Is there a writing standard? Is the original situation described with the necessary details? Are the actions taken detailed? Any new lessons learned?

- Can your production line operators, technicians, and engineers quickly access machine manuals and search for specific sections from anywhere?

The Solution / Value Proposition

An AI chat specialized in your Operation and Maintenance content

The Dharma-AI KM Maintenance Agent

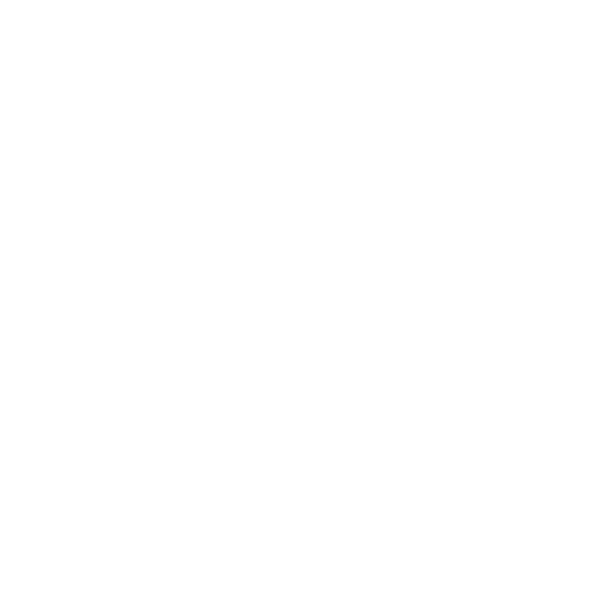

Our solution provides a set of specialized AI Agents for the factory Operation and Maintenance context to organize textual knowledge around your production line.

The Dharma-AI KM Maintenance Agent solution complements your arsenal of failure prediction and reliability models by organizing all textual knowledge about HOW operation and maintenance procedures are performed, regardless of their source.

How does our AI learn about your production line?

We consume this knowledge in any format, which generally comes from the following sources:

- Tickets and Orders from your Maintenance system (we have native integration with SAP PM)

- Machine Manuals (in image or PDF) in any language

- Equipment Downtime Reports

- Factory General Downtime Reports regardless of their source.

Our AI Solution

Benefits of the Dharma-AI KM Maintenance Agent Product

BUSINESS

IMPACT

HOW DO WE GENERATE

THIS IMPACT?

Reduce machine downtime in

Planned or Emergency

Downtimes

Reduce search time for information on similar downtimes

for that equipment

Reduction in Equipment or Line

Restart Time

Ensure that all information

about the equipment’s last downtimes is considered during the restart

Better Line Downtime Planning

List all Recommended and Performed activities during the last Equipment or Line downtime.

And identify all Unperformed routine maintenance Activities to be

considered in the Downtime Planning

Maintenance Knowledge Management

Single repository with maintenance data

regardless of source with associated AI Chat:

- SAP Maintenance Tickets

- Equipment Downtime Reports

- General Downtime Reports

- Machine Manuals